REFRIGERANT LINES REMOVAL/INSTALLATION [MZ-CD 1.6 (Y6)]

1. Disconnect the negative battery cable.

2. Discharge the refrigerant from the system. (See REFRIGERANT RECOVERY.) (See REFRIGERANT CHARGING [MZ-CD 1.6 (Y6)].)

3. Remove the P/S fluid reserve tank.

4. Remove the coolant reserve tank. (See COOLANT RESERVE TANK REMOVAL/INSTALLATION [MZ-CD 1.6 (Y6)].)

5. Remove the front bumper. (See FRONT BUMPER REMOVAL/INSTALLATION.)

6. Remove the washer tank. (See WASHER TANK REMOVAL/INSTALLATION.)

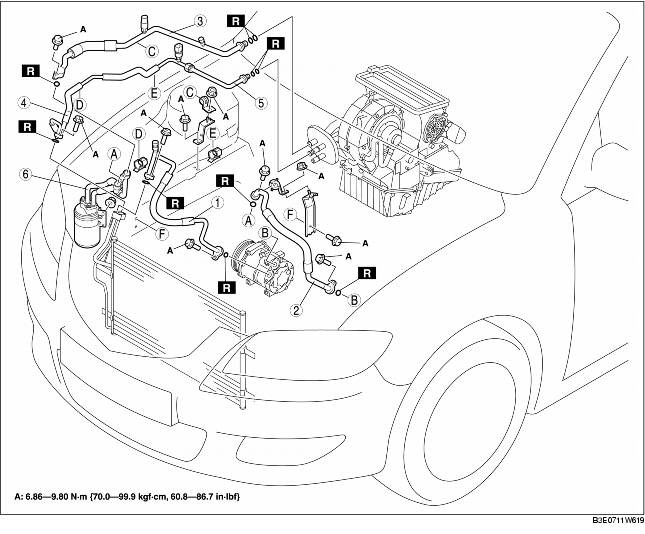

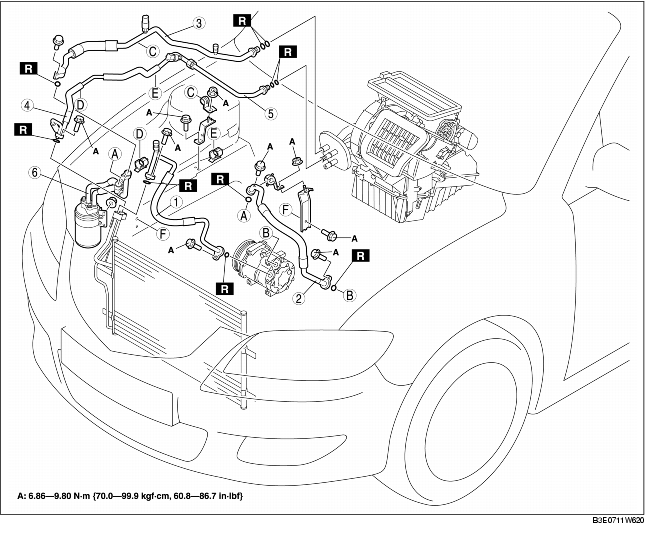

7. Remove in the order indicated in the table. Do not allow compressor oil to spill.

- • If moisture or foreign material enters the refrigeration cycle, cooling ability will be lowered and abnormal noise will occur. Always immediately plug all open fittings after removing any refrigeration cycle parts to keep moisture or foreign material out of the cycle.

8. Install in the reverse order of removal.

9. Perform the refrigerant system performance test. (See REFRIGERANT SYSTEM PERFORMANCE TEST.)

L.H.D.

R.H.D.

|

1

|

Cooler hose (HI)

|

|

2

|

Cooler hose (LO) No.1

|

|

3

|

Cooler hose (LO) No.2

|

|

4

|

Cooler pipe No.1

|

|

5

|

Cooler pipe No.2

|

|

6

|

Cooler pipe No.3

|

Refrigerant Line Removal Note

Nut joint type

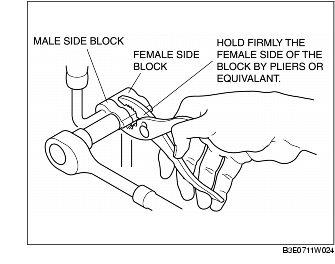

Block joint type

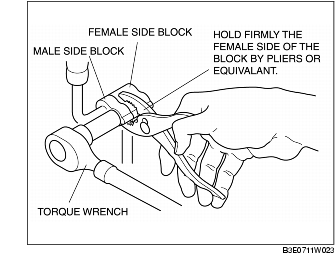

1. Disconnect the block joint type pipes by grasping female side of the block with pliers or similar tool and holding firmly, then remove the connection bolt or nut.

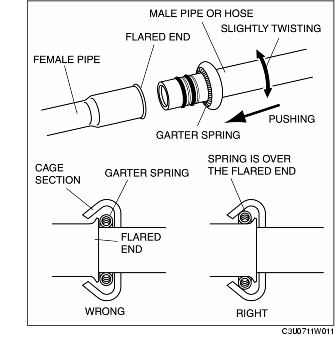

Spring-lock coupling type

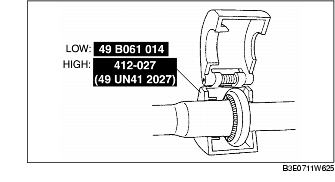

1. Set the SST.

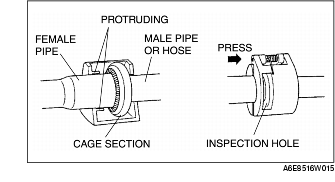

2. While looking through the inspection hole of the SST, insert the protruding part of the SST until it makes contact with the cage section.

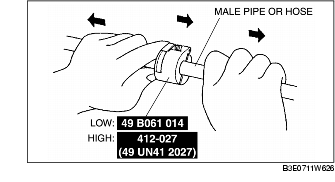

3. Use the SST to disconnect the male pipe or hose from the female by pulling the male pipe or hose.

- • The male pipe or hose can be disconnected easily from the female pipe by pulling from the male pipe or hose while maintaining the pressure of the protruding part of the SST.

Refrigerant Line Installation Note

1. Apply compressor oil to the O-rings and connect the joints.

2. Tighten the joints.

Nut or Block joint type

1. Temporarily tighten the nut or bolt at the connection as much as possible by hand.

2. Tighten to the specified torque using a torque wrench. Tighten the nut joint using a double spanner.

- • Connect the block joints by grasping the female side of the block with pliers or similar tool and holding firmly, then tighten the connection bolt or nut using a torque wrench.

Spring-lock coupling type

1. Connect the male pipe or hose by twisting it onto female pipe until the garter spring at the male pipe or hose is over the flared end of female pipe.

- • When the male pipe or hose is replaced, the indicator ring comes out after connecting to indicate that it is locked.